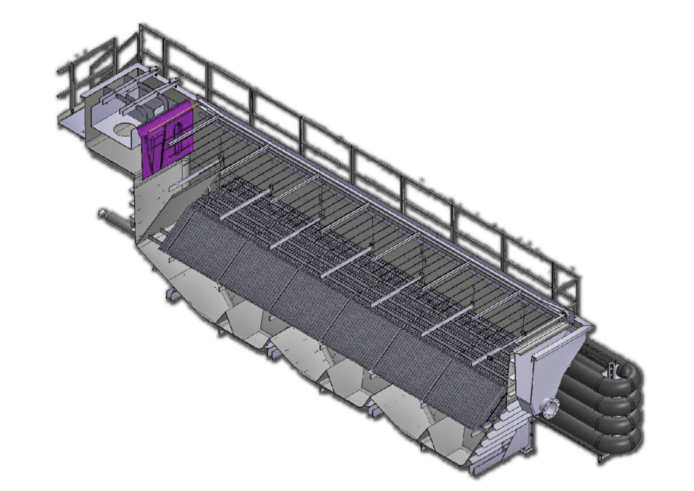

DISSOLVED AIR FLOTATION (DAF)

It allows the separation of solid particles from liquids through advanced flotation technology, FADAR® (high-performance dissolved air flotation).

Thanks to the advanced FADAR® technology, our equipment produces a stream of micro-air bubbles that adhere to the flocs, elevating them to the surface where a scraper system removes the sludge bed generated to the hopper that collects the sludge, achieving a reduction in total suspended solids by up to 90%, reducing COD, and obtaining a sludge dryness of around 6%.

What is F.A.D.A.R technology?

Dissolved Air Flotation units separate solids using FADAR® technology, developed by Toro Equipment, which enhances flotation by injecting micro-air bubbles into the floc. This reduces the density of the floc, creating what we call sponge flocs, thereby increasing the separation velocity. Stokes’ theorem.

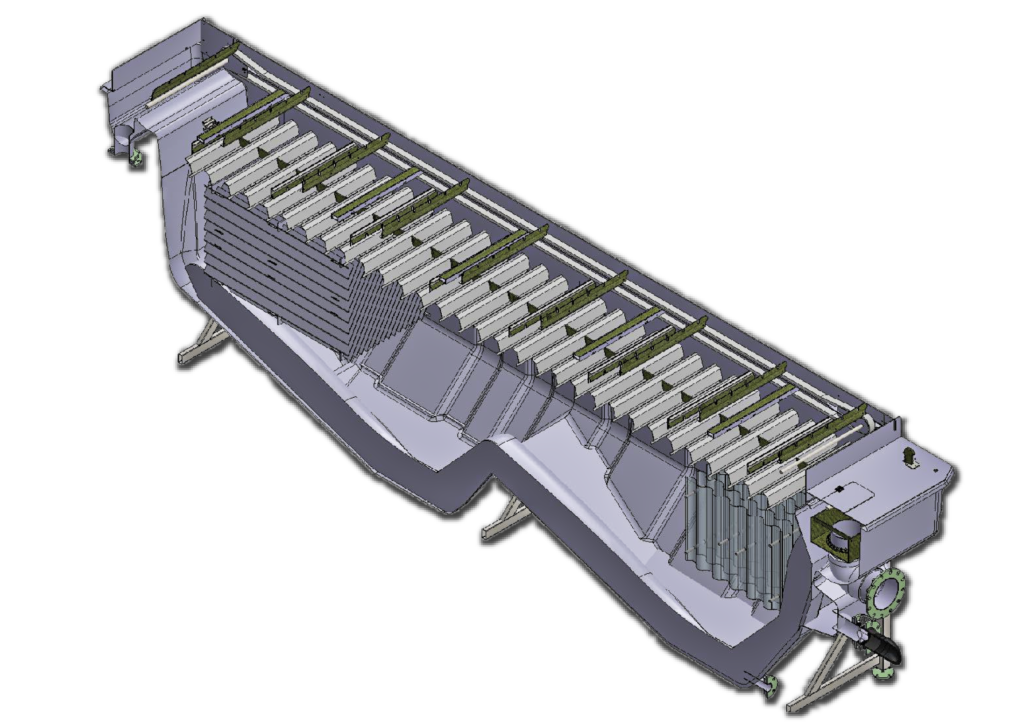

FLOAT TYPES

Open Area Section

Separates between 40 and 60% of solids, particularly those of higher volume.

Lamellar Section

Produces a polishing effect, ensuring high-quality treated water output.

Protected from output overloads.

Solid construction using high-strength infused FRP lamellas, ensuring no collapse. Easy to clean.

FLOAT TYPES

Open Area Section

Water distribution

Lamellar Section

Solid removal flotation

Solid construction using high-strength infused FRP lamellas, ensuring no collapse. Easy to clean

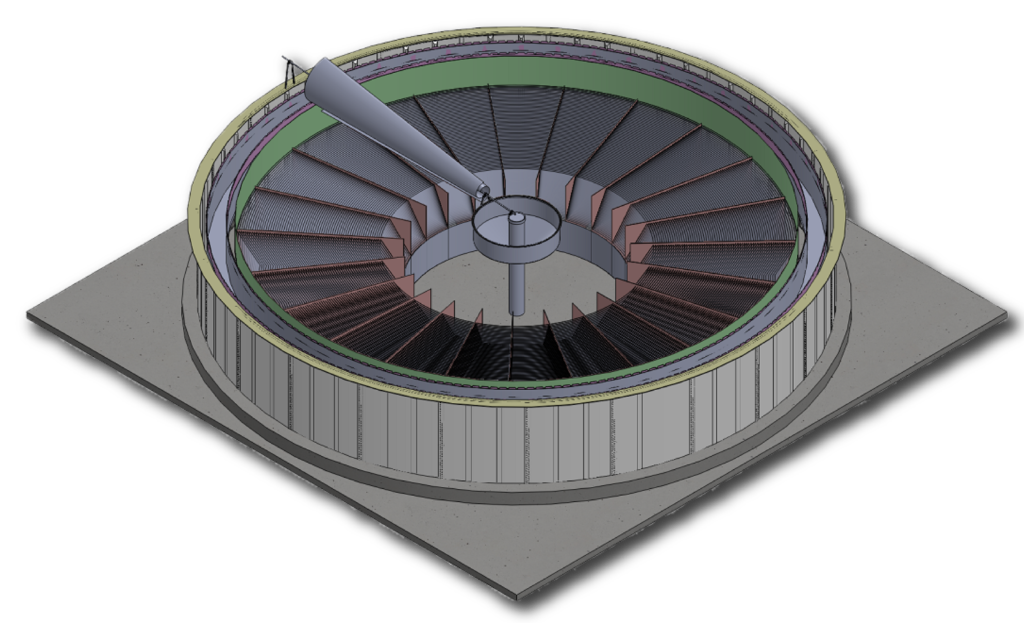

Designed for

Internal osmosis pretreatment

Supply waters from lagoons and marshes