SCREENS

Advantages

Safe designs with high-quality materials

Manufactured in 316 L stainless steel

Components and protections in FRP

Incorporates an effective safety system

Flanges in FRP DIN/ANSI connection

Filter drum cleaning system with pressurized water

Shot blasting finish

Adjustable solid scraper

DEVELOPMENT

We have developed an optional intelligent program for our rotary screens. It is equipped with a frequency converter specifically designed for the motor, ensuring low energy consumption. It operates as a standalone machine that requires no configuration or parameterization, simply plug in and turn on. The TR-Smart® integrates a data log based on historical values, calculating the optimal startup speed in any application, preventing overflow, and the frequency converter adjusts the screen speed automatically.

MODELS

Rotary Screens (TR)

Capacity

From 7 m3/h up to 363 m3/h in clean water

Small flow rates

High performance with high solids load

Smaller filter surface

Description

Produces polished effect, high output water quality

Protected from outlet overloads

Robust, high strength infused GRP lamella construction

Easy to clean.

Rotatory Screens With High Pressurisation System (HPS)

Capacity

From 133 m3/h up to 5864 m3/h

Description

Produces polished effect, high output water quality

Protected from outlet overloads

Solid construction using high-strength infused FRP lamellas, ensuring no collapse.

Easy cleaning

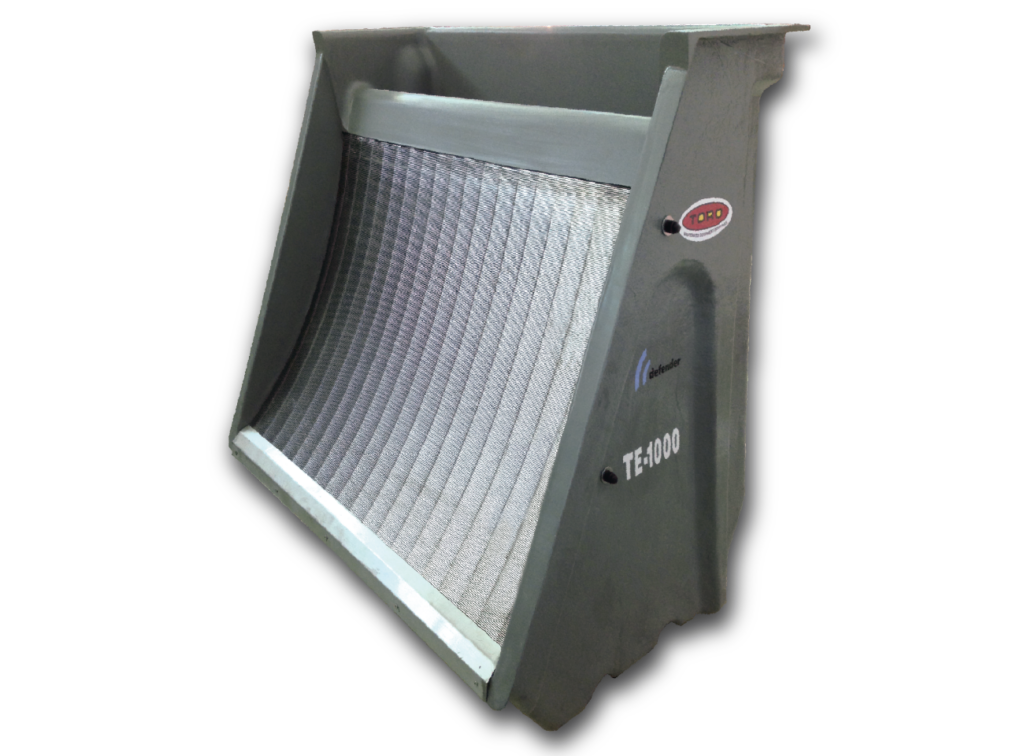

Static Screens (TE)

Description

Its mission is to eliminate the solids carried by the water, in order to avoid clogging and mechanical problems in the installations.

This equipment requires little maintenance and operates continuously, without the need for electricity.

In urban waters, they can replace primary decanters in many cases, providing the elimination of coarse sands and up to 30% percentages of grease and effluent leftovers.

MODELS OF MESHES

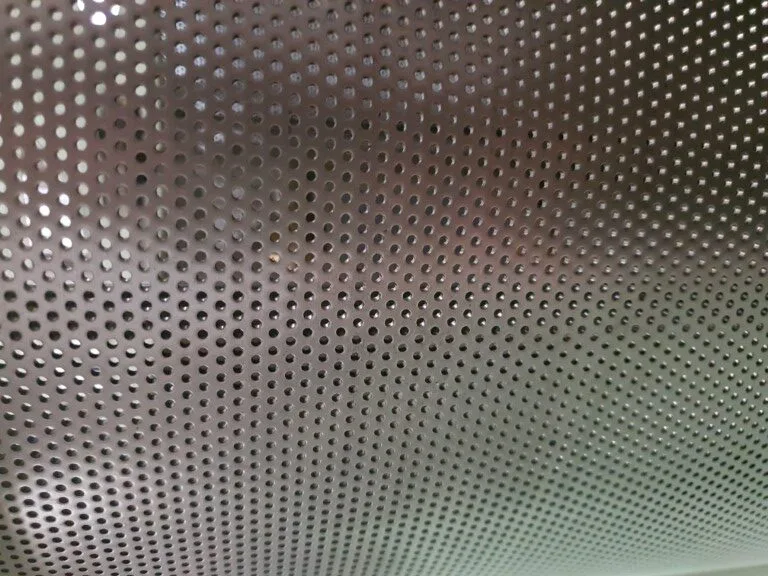

PERFORATED

Mesh size from 2 to 3 mm Ø

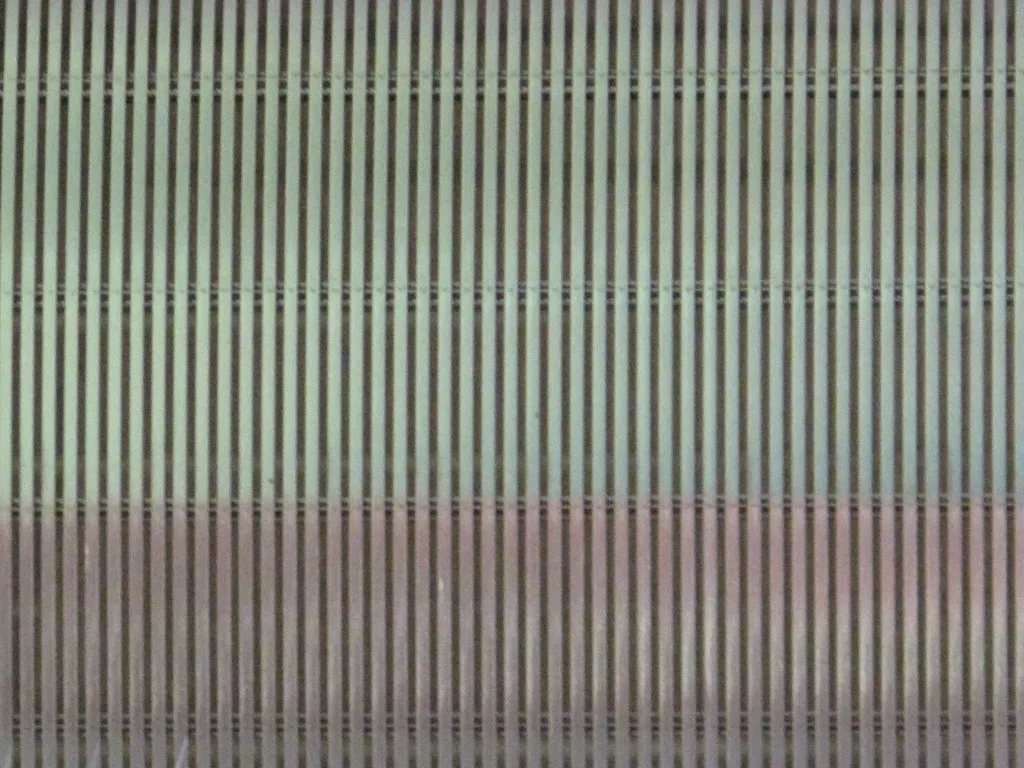

GRID

Mesh size from 0.15 to 2mm

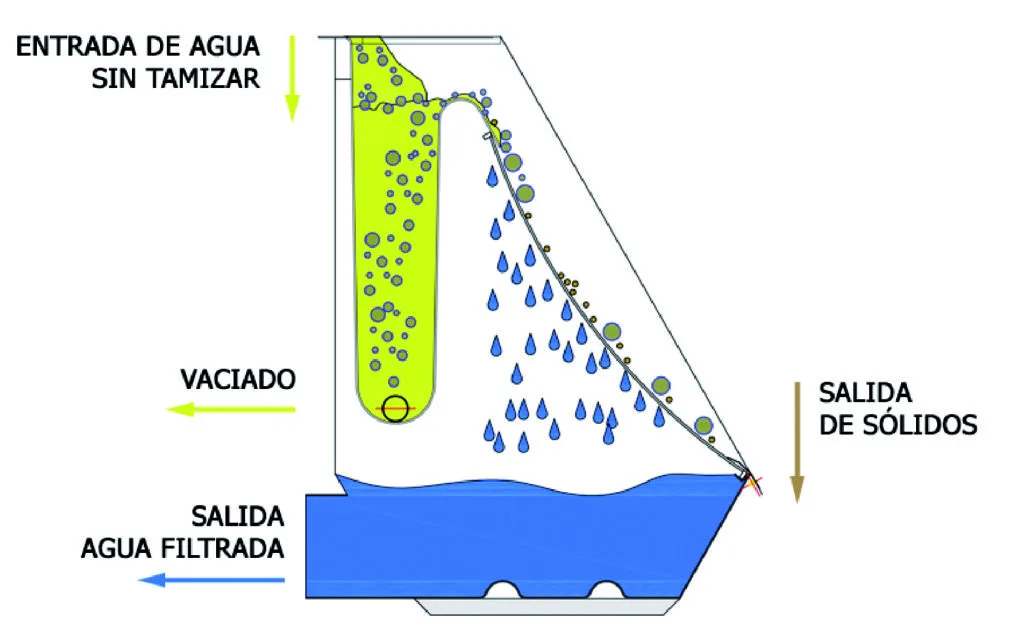

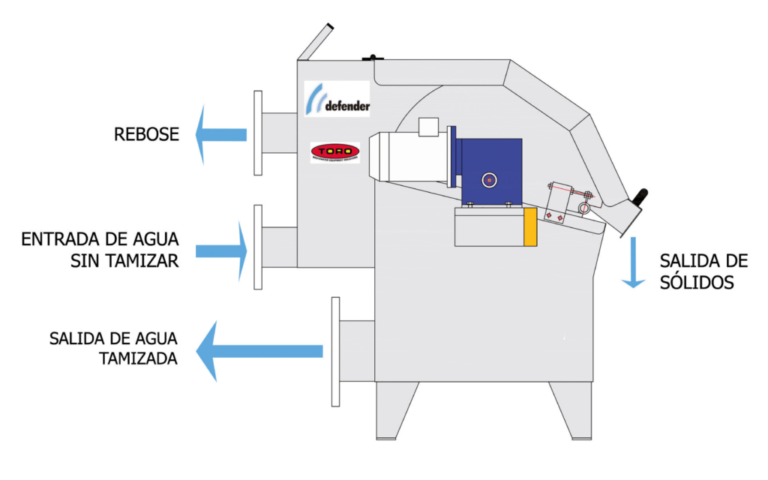

OPERATION

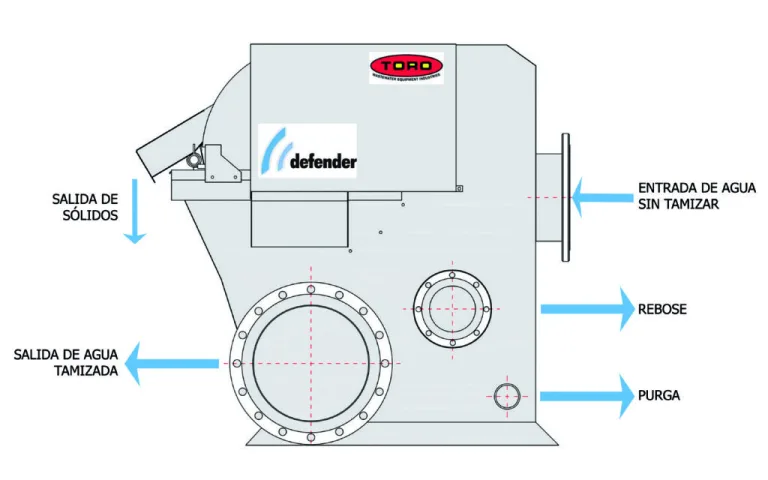

ROTARY SCREEN

The effluent to be treated enters through the flange on the outside of the screen body and is evenly distributed through the spillway and overflow through the filtering drum

The solids are retained on the surface of the drum while it is rotating, the spill penetrates through the mesh opening and performs a self-cleaning function by passing through the lower part of the drum again

As it passes through the outer scraper, the solids are released from the screen and gravity causes the solids to fall off the scraper