MODULAR TANKS

W-Tank® modular tanks, developed by Toro Equipment, are manufactured using GRP (Glassfiber Reinforced Plastic), a high-durability material that is corrosion-resistant and withstands abrasion even in extreme environments. Unlike metallic tanks, GRP ensures a long service life without the need for protective coatings or intensive maintenance.

Thanks to their modular and lightweight design, these tanks are easy to transport and assemble anywhere in the world, with no need for complex civil works. Their structure adapts easily to a wide range of applications, offering a technical and cost-effective solution for both temporary and permanent storage, whether above or below ground, indoors or outdoors.

With capacities of up to 12,535 m³ and heights of up to 11 meters, W-Tank® units are an efficient, safe, and sustainable alternative for companies seeking maximum reliability at optimized cost.

Why Choose W-Tank® Modular Tanks?

Fast and simple assembly: No civil works required, minimal logistics and resources

Modular and lightweight design: Easy to transport, dismantle, and reuse in any location

Maximum durability: Resistant to corrosion, oxidation, and aggressive chemicals

NSF-certified: Suitable for drinking water and validated internationally

Total versatility: Available in multiple shapes, sizes, colors, and with a wide range of accessories

Minimal maintenance: Easy cleaning and long service life reduce operational costs

Low thermal conductivity (0.2107 W/m·K): Excellent insulation against temperature fluctuations

Dielectric properties: Electrical stability and added protection in industrial environments

MODELS

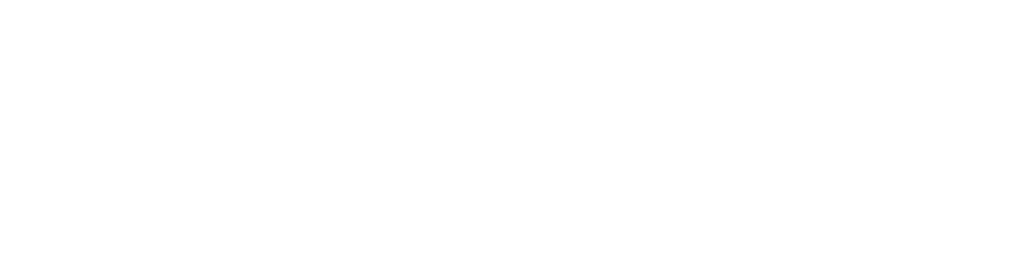

BURGOS

Description

Thermally insulated tanks.

PUR-Insulation coefficient 40 mm of PUR thickness

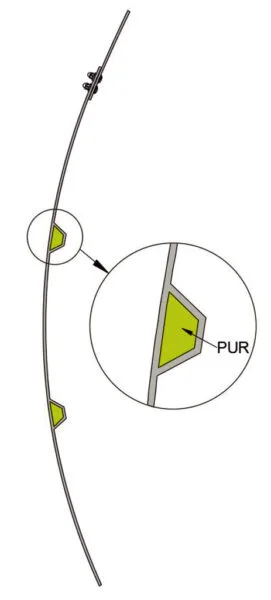

VALLADOLID

Description

100% monolithic

For vertical loads

Decanters

Allows machining on the surface

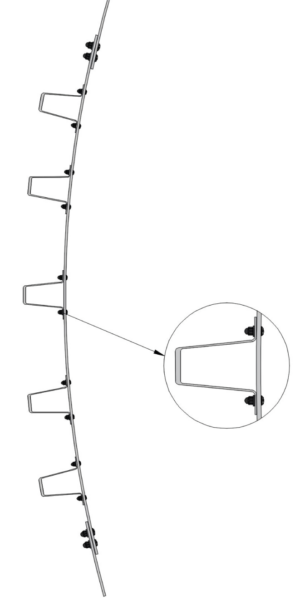

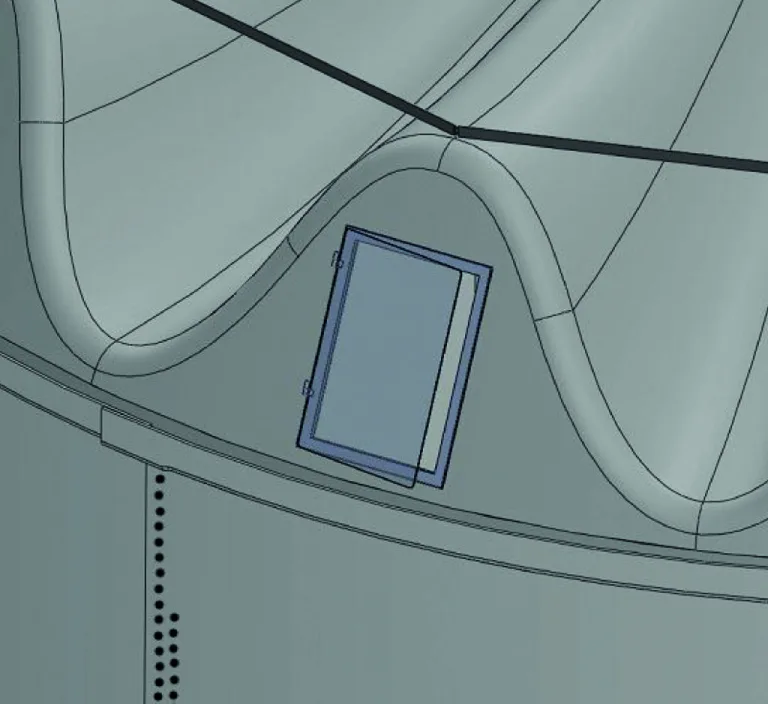

MODELS OF COVERS

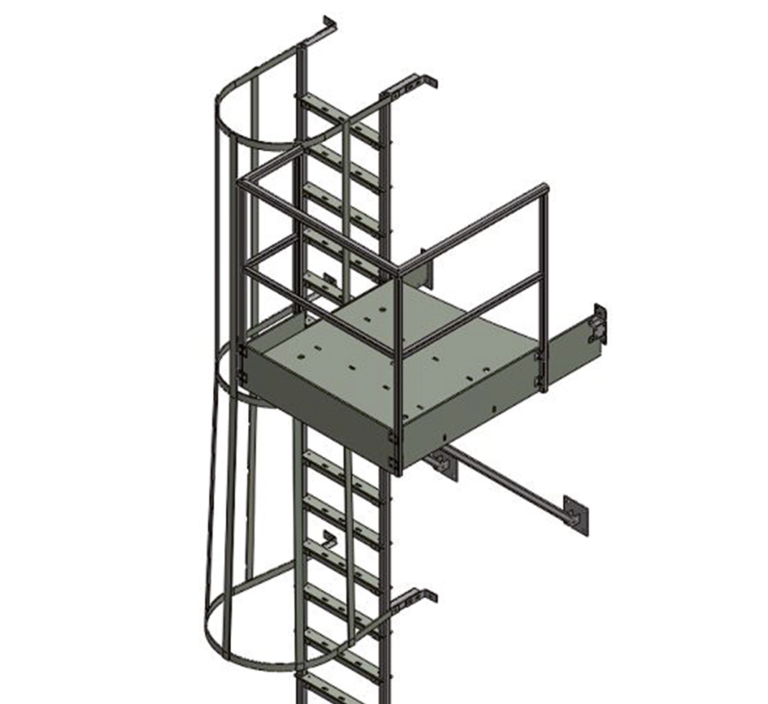

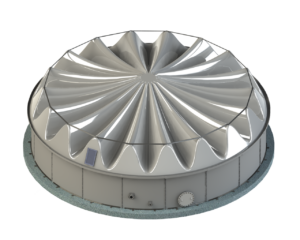

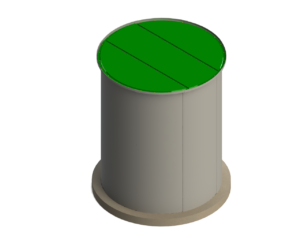

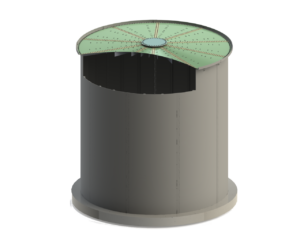

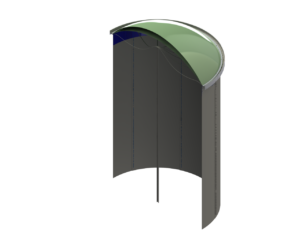

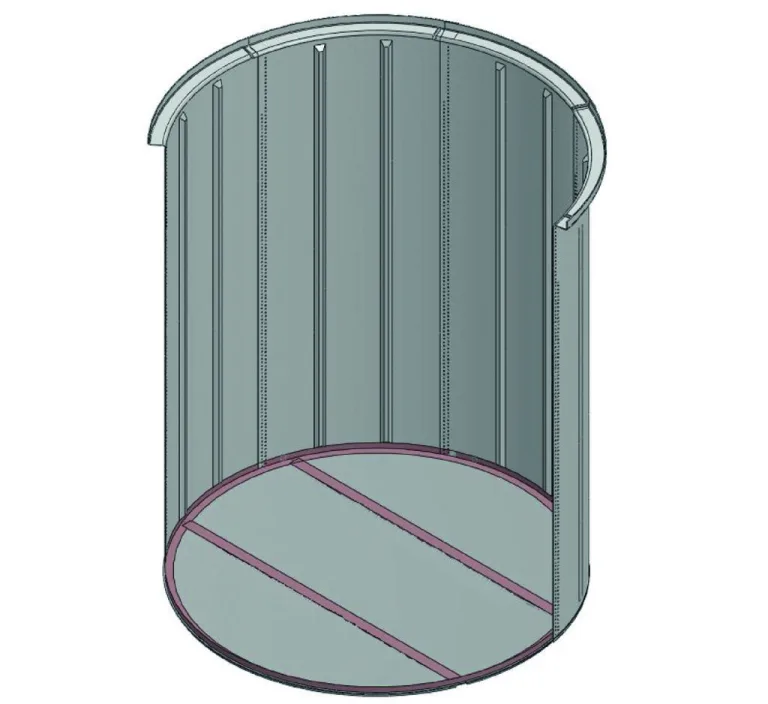

Isometric view of the tank

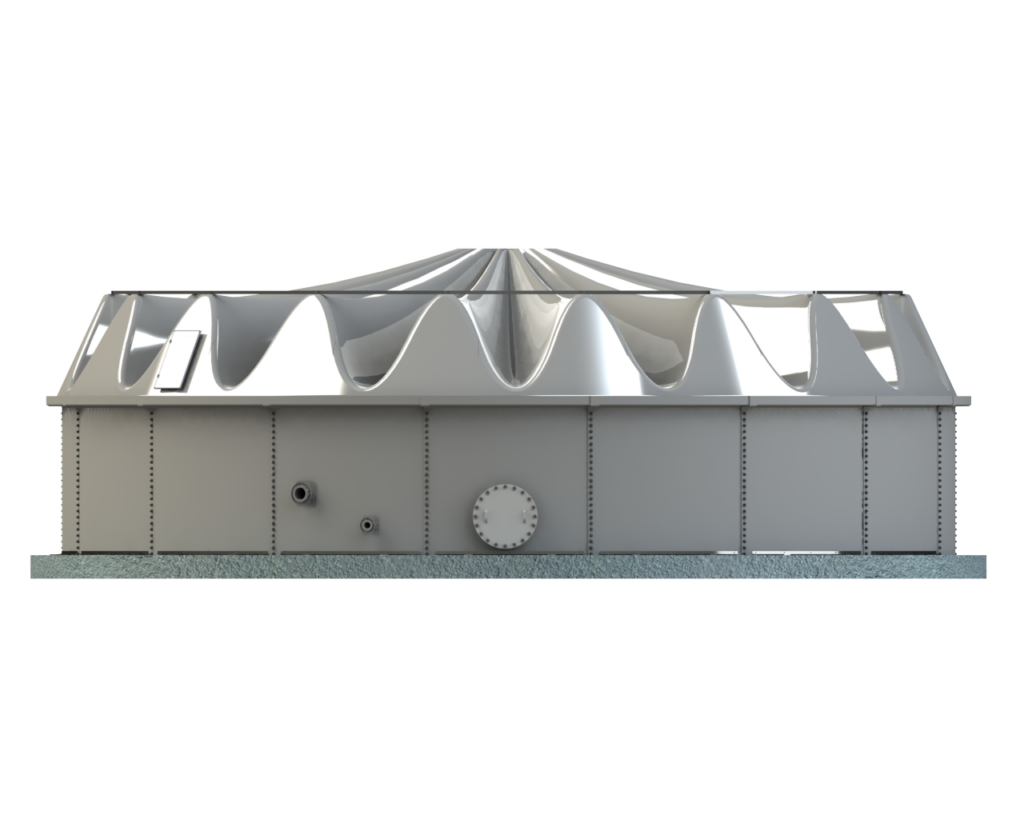

elevation view of the tank

FLAT

CONICAL 15º / 45º

MEMBRANE/GASOMETER

OPERATION

FLEX MOLDING

This manufacturing process employs cutting-edge technology in the composite materials sector. Flex Molding offers several advantages over traditional laminating and infusion methods:

Improved mechanical properties: There's an increase in fiber content, leading to enhanced mechanical properties of the final product.

Enhanced performance of the final product: The reduction in product weight results in improved performance due to decreased resin quantity.

Closed mold manufacturing: Parts are manufactured in a closed mold, improving environmental conditions and workplace quality. Additionally, it contributes to CO2 reduction.

Precise control over thicknesses and fabric orientation: This process allows for precise control over fabric thicknesses and orientations used in part manufacturing.

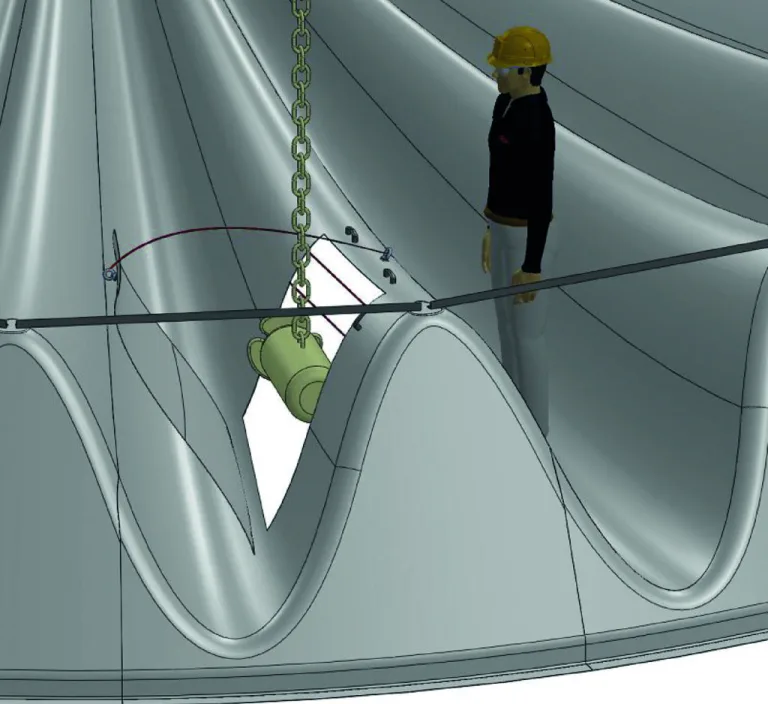

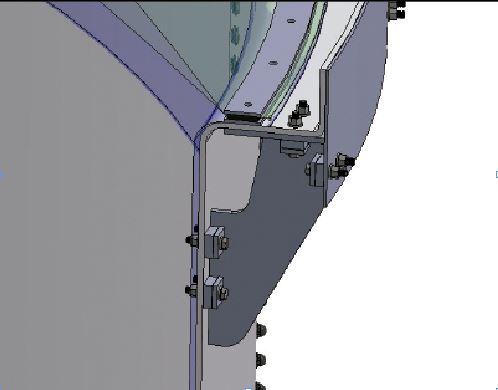

EASY ASSEMBLY

W-Tank® tanks and settlers are easy and quick to assemble, requiring minimal logistical resources.

The product allows for disassembly and relocation for reuse elsewhere.

Assembly instructions are provided.

No civil work needed

OPTIONAL FEATURES AND EXTRAS

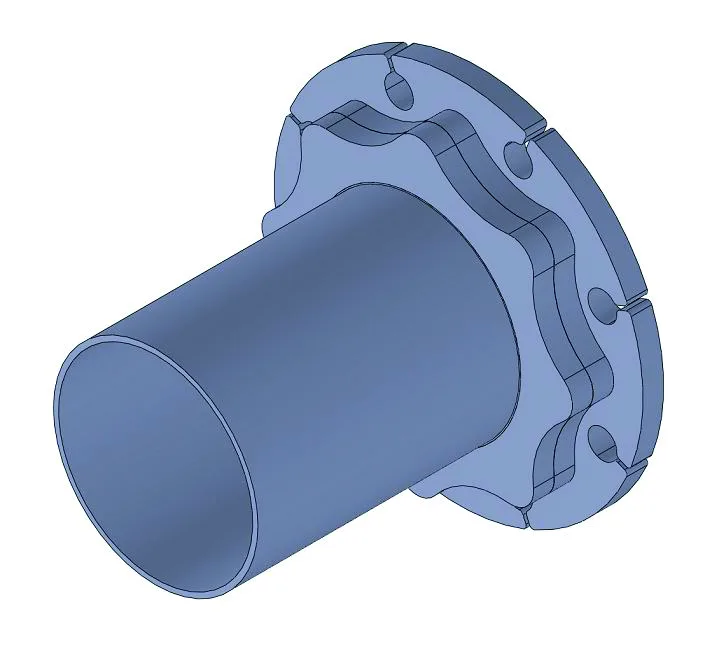

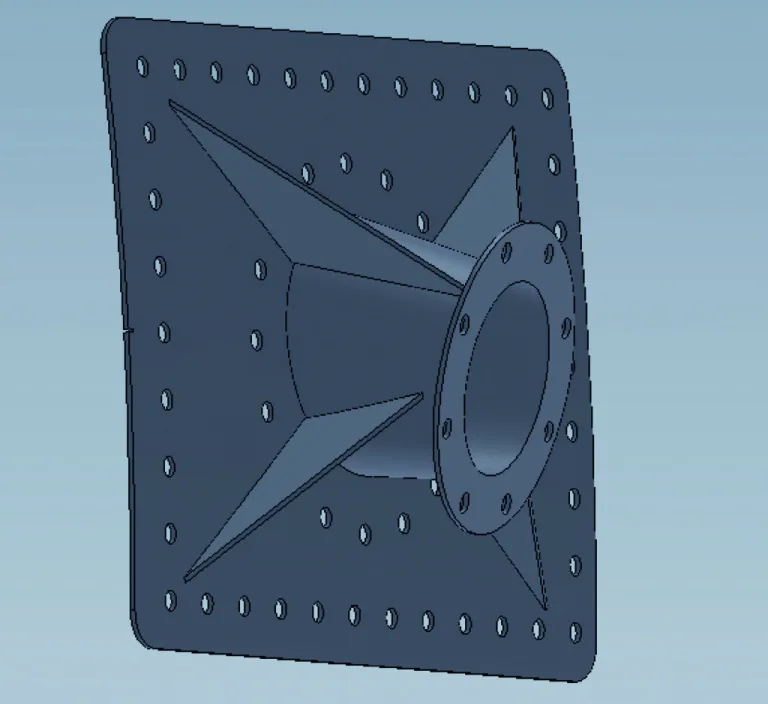

Welded GRP flange

Single flange

Double flange

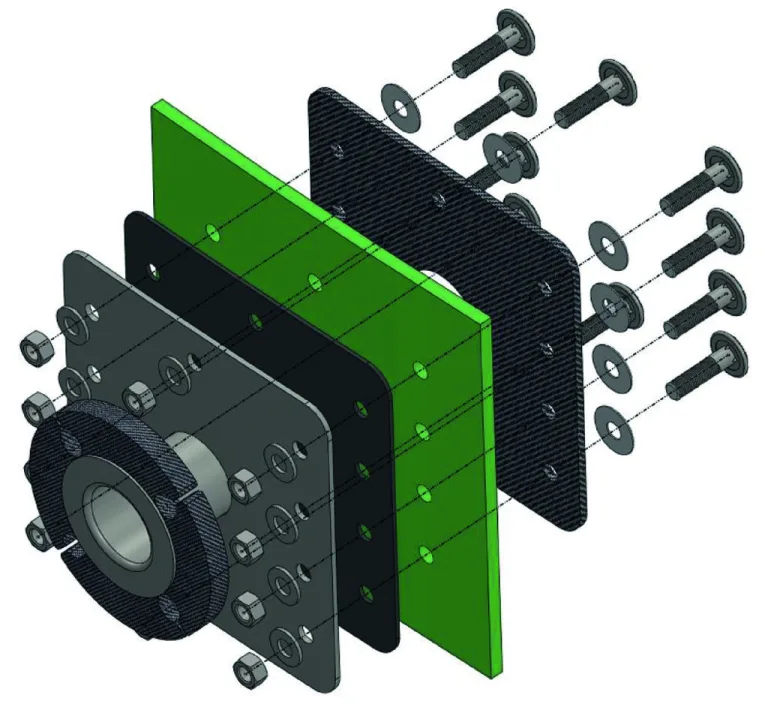

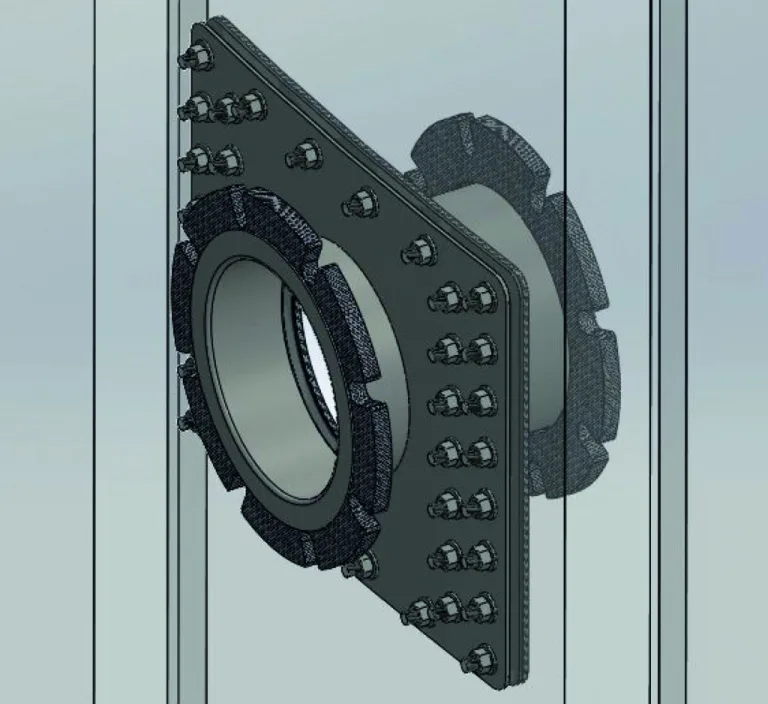

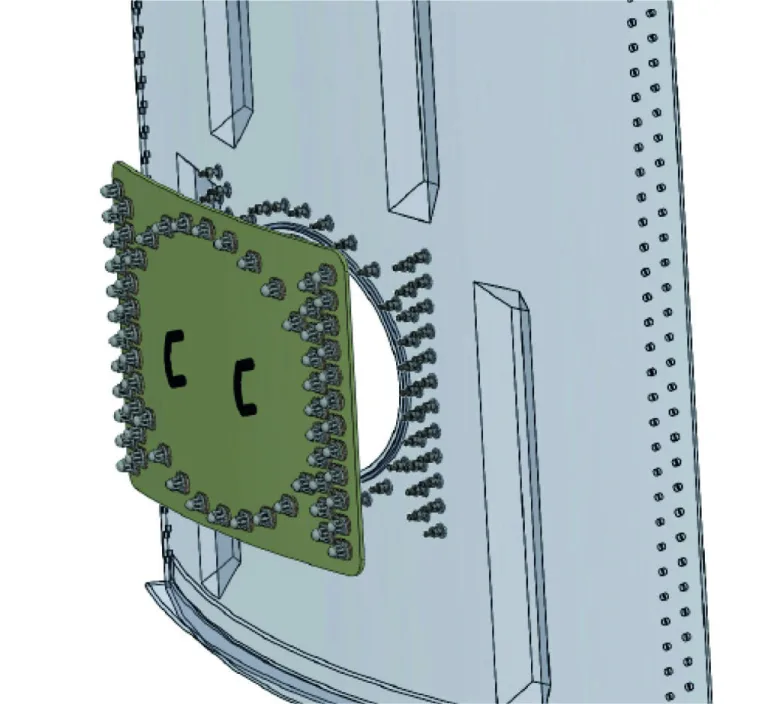

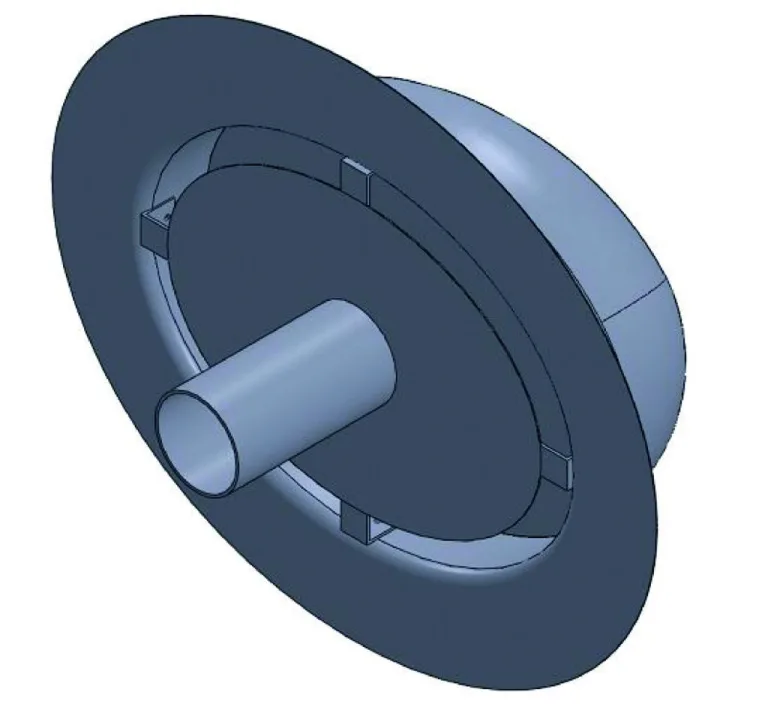

Manhole

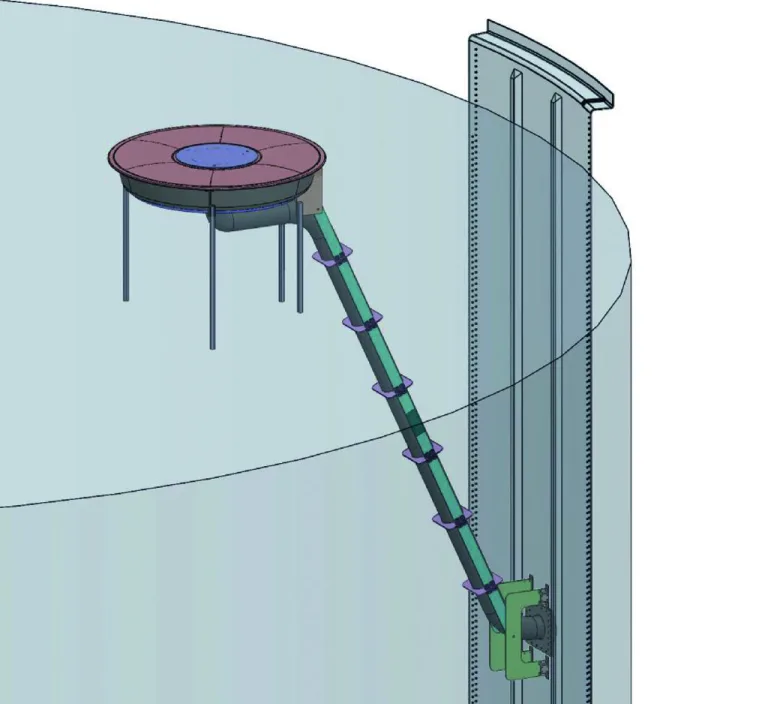

SBR-1900 Decantation Kit

Stirrer bracket

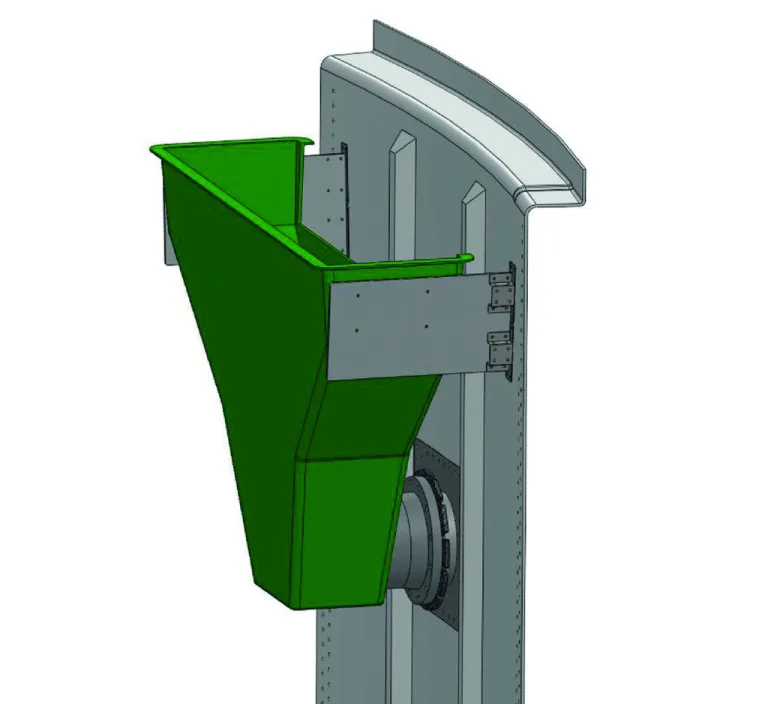

Degassing hopper

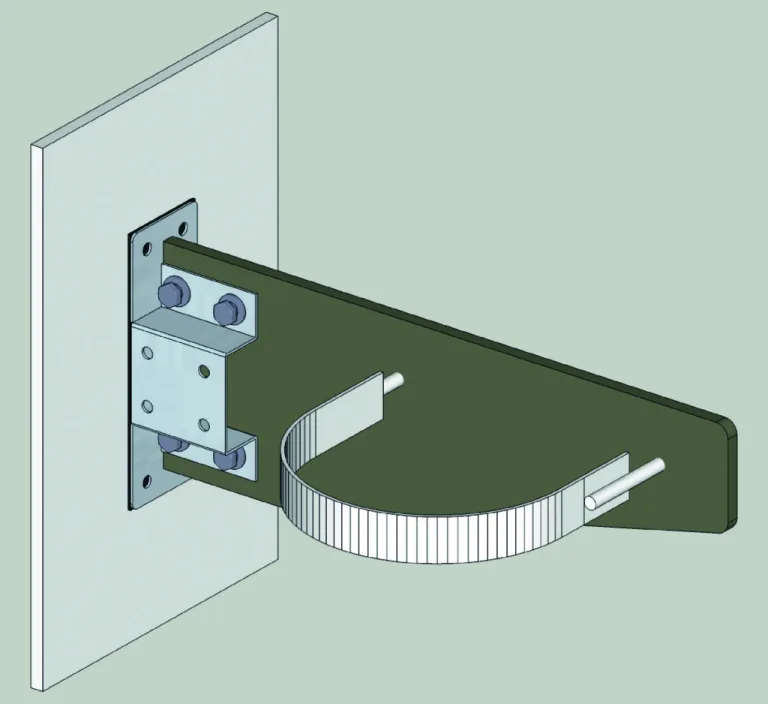

Stainless steel/GRP pipe support

Access window in stirrers

GRP floor

SBR Decantation <=90m³

Preparation for gas holder and membranes

Access window in cover

Stainless steel/GRP ladder