FILTER PRESS

Filter Press for Sludge Dewatering – Maximum Efficiency and Performance

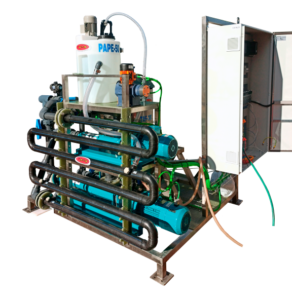

Toro Equipment’s Draco® filter presses are robust and versatile machines designed for the dewatering of sludge generated in wastewater treatment. Their modular configuration and optimized filtration systems allow for high levels of sludge dryness, significantly reducing waste volume and disposal costs.

By transforming sludge into stackable, easy-to-handle cakes, these filter presses offer a key solution to optimize plant logistics, minimize environmental impact, and improve operational efficiency. The result is a cleaner, more cost-effective sludge management process.

Manufactured entirely in-house, Draco® filter presses are built to perform in demanding industrial environments, offering low maintenance and adaptability to various processes, flow rates, and industries.

Why Choose the Draco® Filter Press?

Maximum sludge dryness: reduces sludge volume and transport costs.

Stackable cakes with no overflow: improves logistics and reduces spills.

24/7 operation: automatic cake shaking system ensures continuous performance.

Highly adaptable: fits different flows, sludge types, and treatment requirements.

Low water usage and minimal maintenance.

Durable, high-strength structure: ideal for tough industrial applications.

TYPES OF FILTER PRESS

The range of filter presses comprises five different models. Prolong the lifespan of your equipment with materials manufactured through environmentally conscious processes. All machines, regardless of model and size, are characterized by:

Manufacture using stainless steel St 37-2, AISI 304, and FRP.

Surface finish with epoxy paint to protect them from potential corrosion.

MODELS

Automatic Filter Press (FPA)

Capacity

Maximum filtering surface:

1.5m² to 132.3m².

Maximum number of plates:

5 a 35

Plate size:

470mm to 1500mm

Description

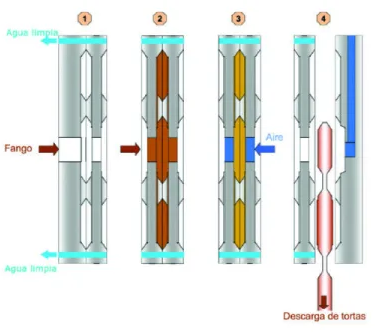

Complete sludge dewatering cycle performed automatically.

Equipped with an automatic cake shaking system.

Semi-Automatic Filter Press (FPSA)

Capacity

Maximum filtering surface:

1.5m² to 64.3m² (1.5m² to 64.3m²)

Maximum number of plates:

5 a 60

Plate size:

470mm to 800mm

Description

Requires operator action for motorized opening and closing of plates.

Manual Filter Press (FPM)

Capacity

Maximum filtering surface:

1.5m² to 64.3m² (1.5m² to 64.3m²)

Maximum number of plates:

5 a 60

Plate size:

470mm to 800mm

Description

The sludge filter cake opening and closing system is mechanically operated via a lever.

Cake discharge using a scraper.

Side-Drag Automatic Filter Press (FPA-AL)

Capacity

Maximum filtering surface:

92 m² to 129 m²

Maximum filtering area:

From 1.5m² to 132.3m².

Plate size:

1200 mm

Description

Complete automatic sludge dewatering cycle.

Suitable only for mineral sludges.

Filter Press with Upper Drag (FPA-AR)

Capacity

Maximum filtering surface:

215 sqm to 310 sqm

Maximum number of plates

125

Plate size:

1000 or 1200 mm

Description

Complete automatic sludge dewatering cycle.

Suitable only for mineral sludges.

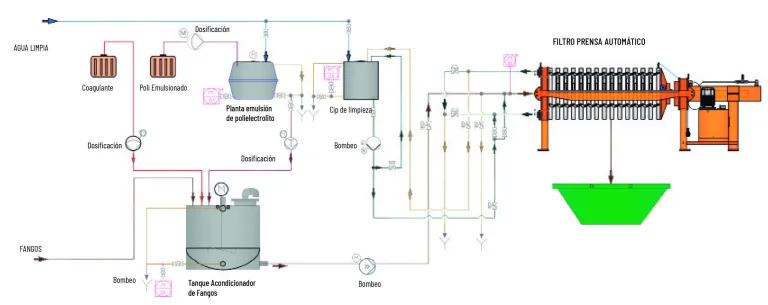

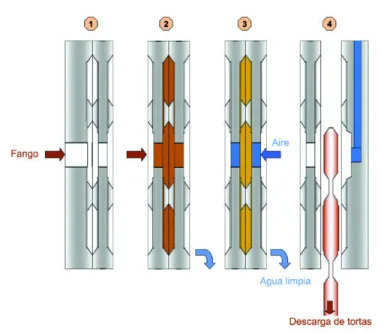

OPERATION

Option for bypass with the installation of different valves.

Facilitates easy inspection of the quality of the filtered liquid.

Enables quick detection of damaged/torn fabric.

WE ADAPT TO YOUR PROJECT

Fabrics

In order to achieve maximum performance of the equipment, each filter press incorporates the most suitable filter cloth for each specific application:

Standard fabrics.

Fabrics with drip-proof frame.

Fabrics for watertight plates.

Special fabrics for aggregate treatment.

Fabrics for other specific treatments.