PRE-ASSEMBLED PLANTS

Containerized & Prefabricated Wastewater Plants – Plug & Play Efficiency Anywhere

Toro Equipment’s prefabricated wastewater treatment plants are designed to deliver compact, efficient, and customized solutions for treating urban and industrial wastewater. Manufactured and tested entirely in our facilities, they are delivered ready to operate, minimizing time, space, and installation costs on-site.

Thanks to their modular and transportable design, these plants can be installed anywhere in the world without civil works, whether in containers or on steel platforms. Each unit includes all essential equipment for a complete treatment process with high levels of automation and reliability.

Why Choose a Prefabricated Plant from Toro Equipment?

Immediate setup, no civil works – Just plug in and start

Space-saving design – Perfect for areas with physical limitations

Fully transportable – Easy relocation by road or sea

Lower operating costs – Assembled, wired, and tested in factory

Flexible configuration – Adapts to any flow, environment, or application

Durable & protected – Can be conditioned for harsh or extreme climates

PRE-ASSAMBLED PLANTS

Containerized Plants

Equipment for wastewater treatment of up to 20m³/h installed within a container suitable for maritime transportation.

Depending on the size of the equipment contained, the containers can be 20', 40', and HC, or multiple containers can be assembled.

Option to condition the container for extreme cold or hot climates.

The machines are protected without the need to construct a building.

Plants On Platform

Treatment plants up to 30 m3/h. Plants on open platforms, with assembly already done and tested at the factory.

They allow for the installation of larger machines than those mounted in containers as there are no walls, facilitating access.

Assembled and tested in the factory to arrive at the installation site and only need to connect the water and sludge inputs and outputs.

MODELS OF CONTAINERIZED PLANTS

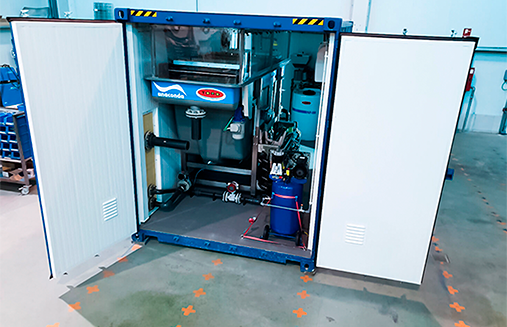

Physical-Chemical Treatment

Defender® Rotary Screen.

Anaconda® Dissolved Air Flotation Unit.

Complete chemical dosing system.

Automatic polyelectrolyte plant.

Intermediate tanks and pumping systems.

Compressed air equipment for supplying pneumatic equipment.

Sludge Dewatering

Draco® Filter Press.

Complete chemical dosing system.

Sludge conditioning tank (TAF).

Complete system for transferring and pumping sludge to the filter press.

Compressed air equipment for supplying pneumatic equipment.