Flocculation and coagulation

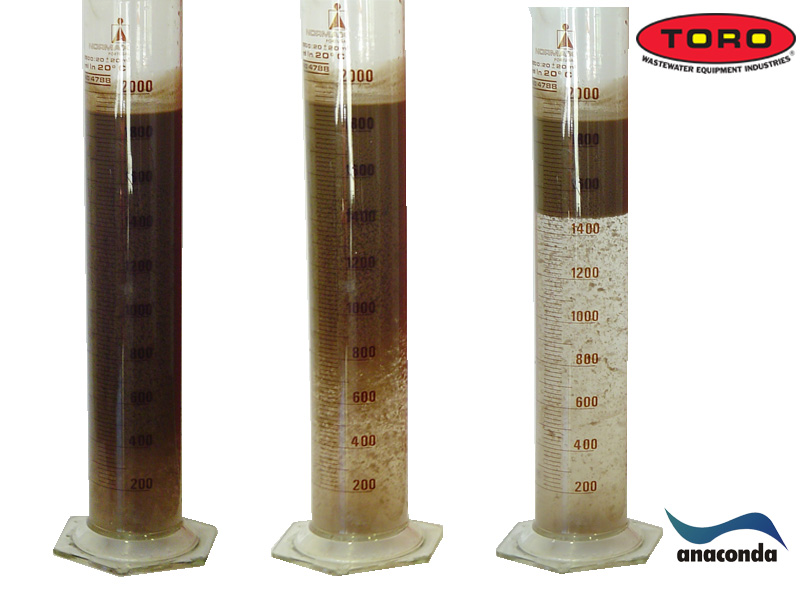

The wastewater is constantly pumped into the flocculation tube, a zigzag-shaped tube that facilitates the mixing of the water with the chemical reagents. The coagulant is added there. This chemical can destabilize suspended particles or colloids to facilitate subsequent solid-liquid separation. Some of the most commonly used coagulants in water treatment are aluminum sulfate, ferrous sulfate, ferric chloride or aluminum polychloride.

Then, in the same tube, the flocculant is added. This is an oppositely charged polymer to attract smaller flocs or colloids to form larger flocs. In this way, micro air bubbles adhere to the larger flocs to create particles with less density than water and make flotation possible.

Sludge on one side, water on the other side

After solid-liquid separation, a portion of the treated water, approximately 30%, is recirculated to be mixed with wastewater. A developed injection system distributes the saturated water pressure in the flotation unit. In this way, the bubbles generated can reach the ideal size to favor floc flotation.

Finally, on the surface of the flotation unit, a scraper system carries the sludge generated towards the hopper to collect it, while the clarified water is discharged into a drainage channel on the opposite side. Meanwhile, the heavier particles that could not reach a density lower than that of the water are kept in the sedimentation chamber to be recirculated to the beginning of the water treatment line and receive the appropriate treatment.